Directional drilling in Peace River is not just about machines and mud—it is about precision, planning, and protecting the land while getting the job done right. If you want to master this craft, you need to understand the ground, choose the right tools, train your crew, and follow smart steps from start to finish. This guide will walk you through everything in a simple and clear way, so you can feel confident and ready for success. Let’s start with the basics and build your knowledge step by step.

Understanding the Ground Beneath Peace River

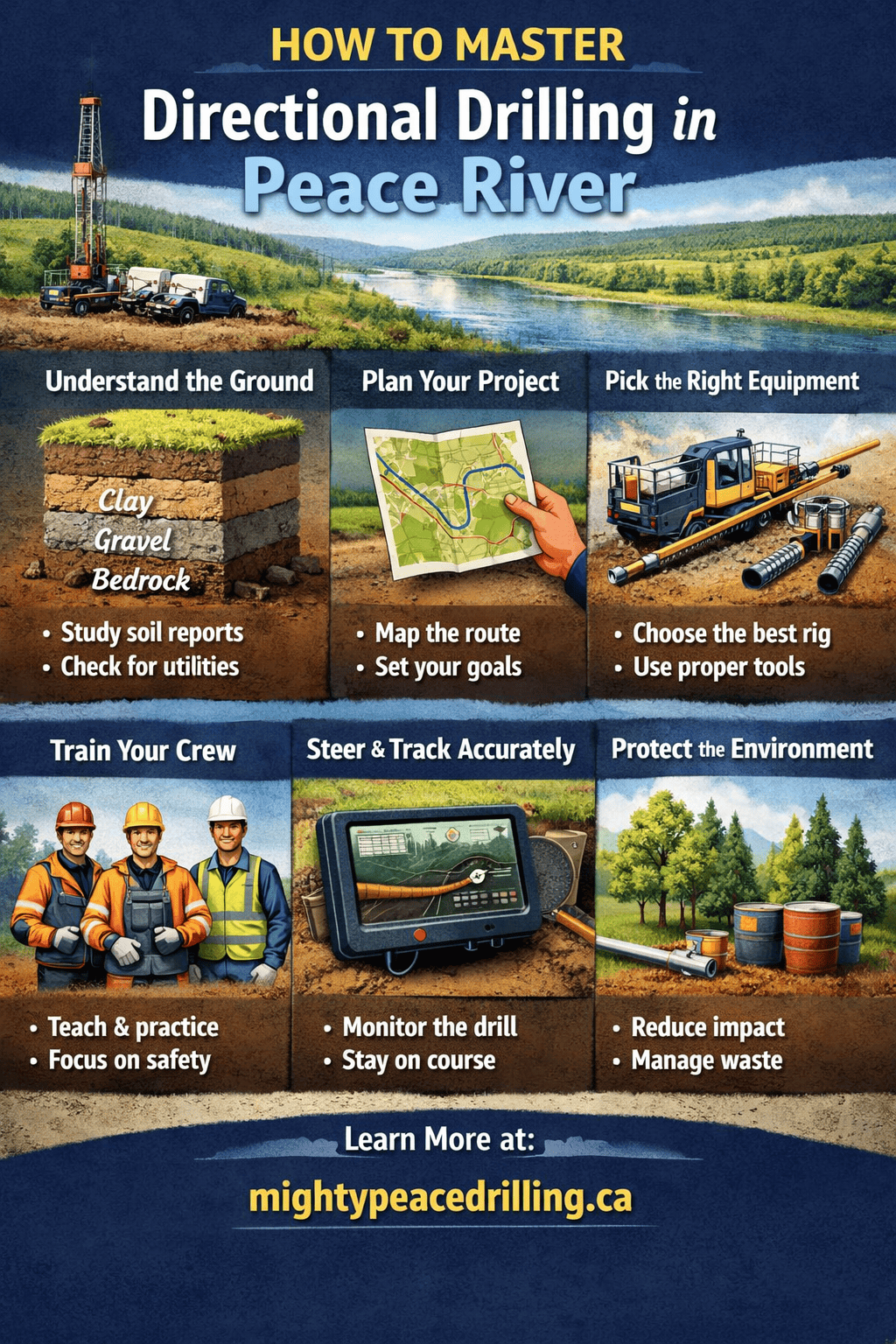

Every great drilling project begins with knowing the land. In Directional Drilling Peace River projects, this step is even more important because the region has unique soil, rock layers, and water tables. Some areas have soft clay, while others contain gravel or hard rock. Each type of ground changes how you drill. If you skip this step, problems can appear fast.

Before drilling begins, study soil reports and conduct proper site checks for your Directional Drilling Peace River work. Look at past project data in the area. Test the ground strength and locate underground utilities. When you understand what lies below, you can plan with confidence. And planning well is the first sign of mastery.

Why Directional Drilling Is So Valuable

Traditional digging tears up roads and landscapes. Directional drilling, on the other hand, creates underground paths with minimal surface damage. That means fewer traffic problems, less harm to nature, and lower repair costs.

In Peace River, where land and environment matter deeply, this method is especially useful. It protects green spaces and reduces disruption to communities. When you see how much cleaner and smarter this process is, you’ll understand why it’s growing in demand. But how do you actually become great at it?

Start With Strong Project Planning

Success in drilling always starts long before the first hole is made. A clear plan saves time, money, and stress. Define your goal first. Are you installing pipelines, cables, or utility lines? The answer will shape your drilling design.

Map the drilling path carefully. Choose entry and exit points with care. Plan the drill angle and depth based on soil data. Think about safety at every stage. When your plan is detailed and realistic, you reduce risk and boost results. And strong planning leads naturally to the next key skill—choosing the right tools.

Choosing the Right Equipment Matters

Not all drilling rigs are the same. Smaller rigs work well in tight urban areas. Larger rigs handle longer distances and tougher ground. Selecting the right machine is a major step toward mastering Directional Drilling Peace River projects.

Drill bits must match the soil type. Mud systems must maintain bore stability. Tracking systems must provide accurate guidance underground. Modern equipment with updated technology improves precision and reduces mistakes. When your tools are reliable, your results improve instantly. But tools alone are not enough—you also need skilled hands.

Build a Skilled and Trained Crew

Machines do not replace people. A trained crew makes the real difference. Operators must understand steering systems, fluid management, and safety rules. Spotters must know how to track bore paths accurately. Supervisors must react quickly if conditions change.

Ongoing training keeps skills sharp. Practice emergency drills. Teach problem-solving methods. Encourage teamwork and clear communication. A confident team works faster and safer. And when your crew works smoothly, your project flows without delays.

Master the Art of Steering and Tracking

Directional drilling is like guiding a tunnel blindly under the earth. Precision is everything. Steering tools allow operators to adjust direction while drilling. Tracking systems show the drill head’s location and depth.

Pay close attention to real-time data. Small corrections prevent large mistakes. Stay calm and patient during adjustments. Quick reactions and steady focus help avoid hitting utilities or straying off course. When you control direction perfectly, you truly begin to master the craft.

Understand Drilling Fluids and Their Role

Drilling fluid, often called “mud,” is more important than many people think. It cools the drill bit, removes soil cuttings, and keeps the bore stable. Without proper fluid management, the hole can collapse or clog.

Use the correct mixture for the soil type. Monitor pressure levels and flow rates. Adjust quickly if conditions change. Good fluid control protects your equipment and keeps operations smooth. This often-overlooked detail can make or break a project.

Focus on Safety at Every Step

Safety is not optional. It is essential. Before starting, conduct a safety meeting with your team. Identify risks like underground utilities, unstable soil, or equipment hazards.

Wear proper protective gear. Follow local regulations. Keep communication clear and constant. A safe site protects workers and builds trust with clients. And when clients feel secure, they are more likely to recommend your services.

Protect the Environment and Community

Peace River values its natural beauty. Responsible drilling respects that. Use methods that limit soil disturbance. Dispose of drilling fluids properly. Avoid unnecessary tree removal.

Communicate clearly with nearby residents and businesses. Inform them about timelines and possible noise. Transparency builds goodwill. When your project leaves the area clean and intact, your reputation grows stronger with every job.

Solve Problems Quickly and Calmly

Even with good planning, challenges may appear. You might hit unexpected rock. Weather may shift. Equipment may need repair. Mastery means staying calm and thinking clearly.

Have backup tools ready. Keep spare parts on site. Maintain open communication within your crew. Quick problem-solving reduces downtime and saves money. Each solved issue makes your team more experienced and confident.

Invest in Ongoing Improvement

Technology in drilling keeps evolving. New tracking systems, better drill bits, and smarter software appear every year. Stay updated with industry trends. Attend workshops and training events.

Review completed projects and look for ways to improve. Ask clients for feedback. Small changes often lead to big improvements. When you commit to learning, you stay ahead of competitors.

Build Trust Through Quality Work

Clients look for reliability. Finish projects on time. Stick to budgets. Maintain clear communication. Deliver clean and accurate results.

Word of mouth matters greatly in Peace River. One successful project often leads to another. Strong relationships grow your business steadily. And trust is the foundation of long-term success.

Partner With Proven Experts

Sometimes, the fastest way to master something is to learn from experts who already excel. Companies experienced in Directional Drilling Peace River understand local soil, weather, and regulations deeply. Working with professionals who know the region can shorten your learning curve and reduce costly mistakes.

For reliable expertise and trusted service, many in the region turn to Mighty Peace Drilling. Learn more about their services at mightypeacedrilling.ca.

Bringing It All Together

Mastering directional drilling in Peace River is not about luck. It is about preparation, precision, safety, and continuous learning. Study the land. Plan carefully. Choose the right tools. Train your team. Protect the environment. Solve problems calmly. Improve constantly.

When you follow these steps, you move from simply drilling to truly mastering the craft. And once you master it, each new project becomes an opportunity to grow even stronger.

Questions

What makes directional drilling better than traditional trenching?

Directional drilling creates underground paths without digging large trenches. This reduces surface damage, protects roads and landscapes, and lowers restoration costs.

How long does a typical directional drilling project take in Peace River?

Project time depends on length, soil type, and weather. Small jobs may take a few days, while larger projects can take several weeks.

Is directional drilling safe for the environment?

Yes, when done correctly. It minimizes surface disruption and protects natural areas. Proper planning and fluid management help prevent environmental harm.